Project Name: Working Performance Control Method of Freshly Mixed Concrete Based on Performance Target Regulation of Cast-In-Place Pile Construction

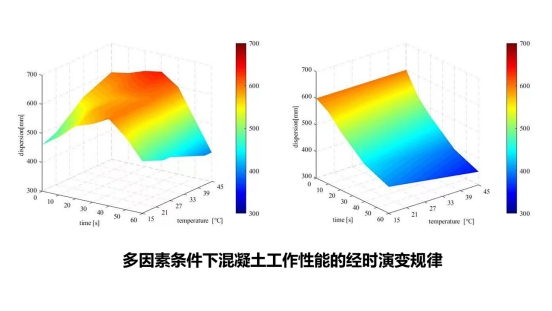

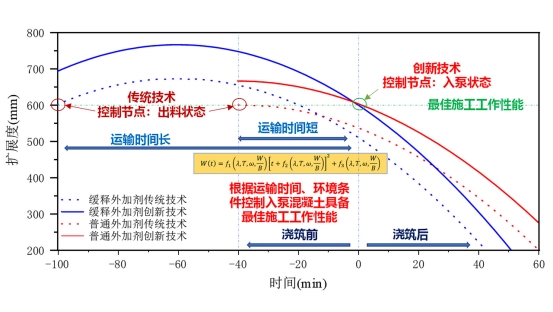

Introduction: Centering on the working performance control of infrastructure concrete at the cast-in-place pile construction node, the project studied loss rule of the working performance of newly mixed concrete during transportation under different ambient temperatures, and revealed the influence mechanism of temperature, slow release of admixtures and early hydration of cementitious materials on loss of working performance of freshly mixed concrete under different mix ratio parameters. The evolution model of concrete working performance under different environmental conditions is established, which can accurately predict the working performance change rule of concrete. Aiming at the working performance control requirements of concrete at the cast-in-place pile construction node, the working performance of newly mixed concrete is adjusted, so that the bad conditions of dry, hard, segregation and bleeding do not occur when concrete is transported to the site for construction, so as to ensure the quality of concrete.

This working performance control method of newly mixed concrete formed by the project based on the objective regulation of the construction performance, It has provided key technical support for concrete performance design, regulation and guarantee of major projects such as Zangmu Yarlung Zangbo River Bridge, Pingnan Third Bridge, Longtan Tianhu Bridge, Jinshajiang Bridge of Sichuan-Tibet Railway, Jinsha River Bridge and other major projects. This technology has broken through the record of continuous pumping of 1013 square meters of concrete under the extreme environment of high altitude and large temperature difference, and helped fill concrete in the ultra-long and ultra-high pumping distance pipe of 575m super-span arch bridge.

Unit: Guangxi University

Finisher: Academician Zheng Jielian and his team members